Have you ever considered the aspects that influence a vehicle's performance? Most people connect automobile performance with power, speed, the roaring sound of the engine, and the ability to accelerate from zero to x miles per hour. But all this power, speed, and other factors become useless if the driver cannot control his truck and feels uncomfortable driving.

The suspension system oversees keeping your truck driving smooth, even on bumpy surfaces, and allowing you to maintain vehicle control. Therefore, the suspension system is a critical component of a vehicle. Now we can look at the various parts of a suspension system and how they work.

Functions of the vehicle suspension system

●Support the weight of the vehicle

●Absorb satisfactorily larger and smaller road impact

●Reduce the rolling or pitching of the body

What are the parts that make up a suspension system?

The following components make up a suspension system:

●Bushings

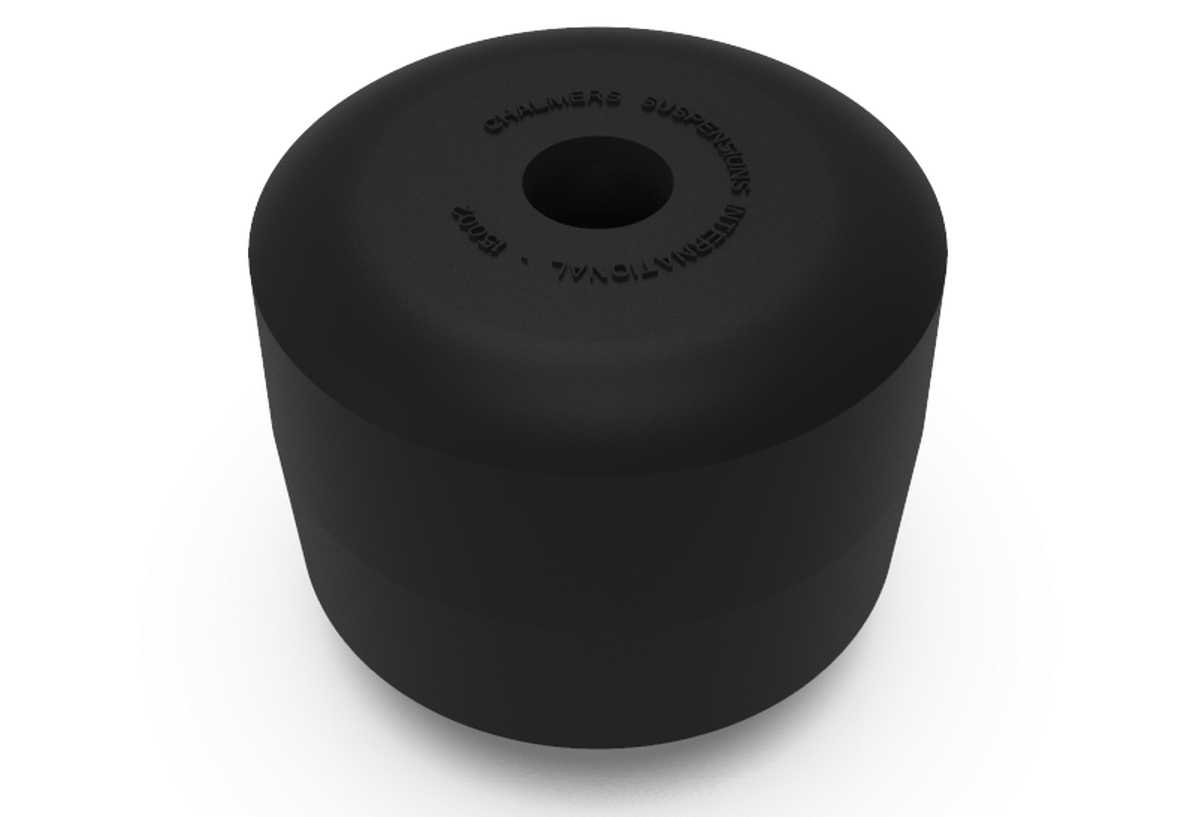

Bushings are the rubber pads attached to the suspension system. They are also known as rubbers due to their material composition. The essential function of bushings is to absorb the shock of turbulence along the road during a drive. Bushings buffer the tremors caused by imperfect surfaces and allow for a smoother riding experience. Aside from rubber, bushings can also be made of polyurethane or other soft-yet-firm materials.

Bushings wear down at different speeds in different vehicles. It depends on the working environment and the amount of stress put through it regularly. Due to the lack of suitable suspension, bad bushings make driving difficult.

●Torque rod

In truck and trailer suspensions, the torque rod plays multiple roles. The torque rod regulates the driveline angles, prevents the axle housing from rotating while accelerating and braking, locates the axle, maintains the alignment, absorbs leaning and corning forces, and links different parts of the suspension system together.

Replacement of the torque rod is needed when the torque rod is bent, or the mounting bolt hole is damaged. Damaged torque rods could lead to unsteady steering like shaking or swaying during lane changes and thumping or banging sounds when decelerating or going around turns.

●Spring

Chalmers Rubber spring compensate for the irregularities in the road surface, keep the suspension system at a predetermined height and sustain additional weight without excessive sagging. It is critical in delivering comfort, precise handling, and load-bearing capability - the three essential areas where customers will have concerns.

Springs sag as they age and lose their capacity to bounce again. Weak springs don't carry their fair share of the overall load, which leads to unpredictable behaviour when cornering, braking, or accelerating.

●Shock absorber

Shock absorbers are essential components that eliminate or dampen sudden shock waves in a vehicle's suspension system. They keep the undesirable and excessive spring motion in check. A shock absorber's main job is to absorb or dampen the compression and rebound the springs and suspension. It also reduces the undesired and excessive spring motion, ensures the tires are always in contact with the road, and ensures the safest control and quickest braking response.

Bottom line

If you start to feel discomfort

while driving, pulling to one side or the other, the corner of your

truck seems to be lower than the others, and difficult steering, it is time to

check and replace the associated parts of the suspension system.

Find every part for your suspension, visit Truck Suspension-Parts for best deals on the original suspension parts delivered by the manufacturer.